Case: Farges Bois, France – Nouvelle-Aquitaine

Optimizing the settings on our sawing line

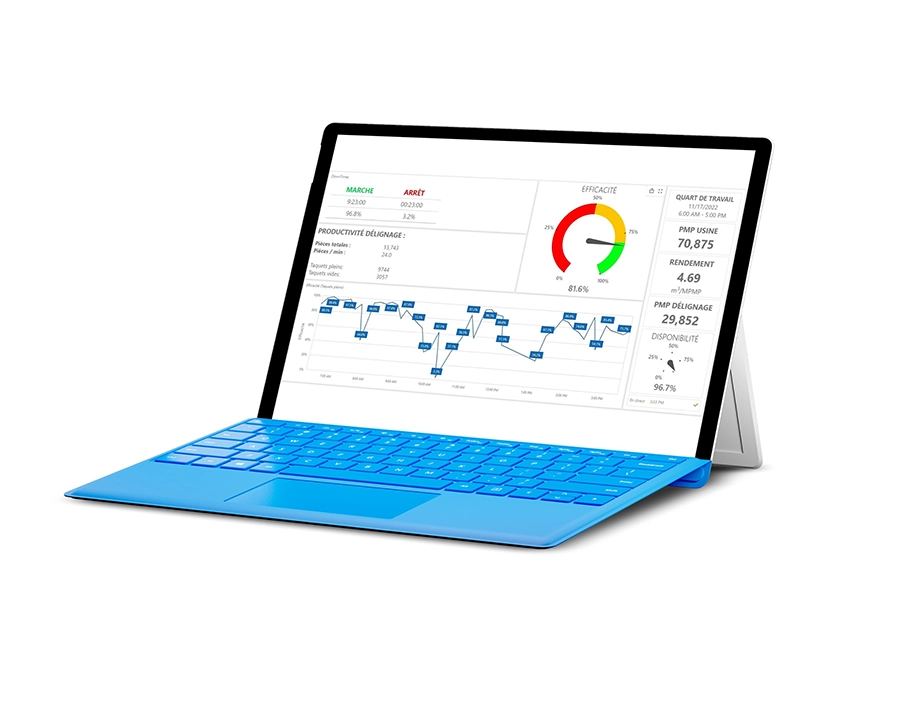

Continuous dashboard use on a daily basis. Data analysis is crucial to every plant’s future. Business intelligence is coming to every plant operation and it’s an opportunity to be seized without delay. EFFECTO contacted our equipment supplier, Prologic, in Phase 1 to extract the data. From there, intensity and meterage tracking curves were created to see if a machine was straining or running at the right rate for the current run.

We used to make estimates based on our experience. Today we have reliable data, the real numbers, so we can make correlations between wear and tear on the machine and the level of intensity. We get an alert as soon as it reaches a peak and we intervene just in time.

In Phase 2, we accelerated the batches we could and slowed down the ones with the potential of damaging the equipment.

With the sawing dashboard, we know right away where we are most efficient.

Hervé Leymarie, Sawmill Production Manager